We Move Air And Us!

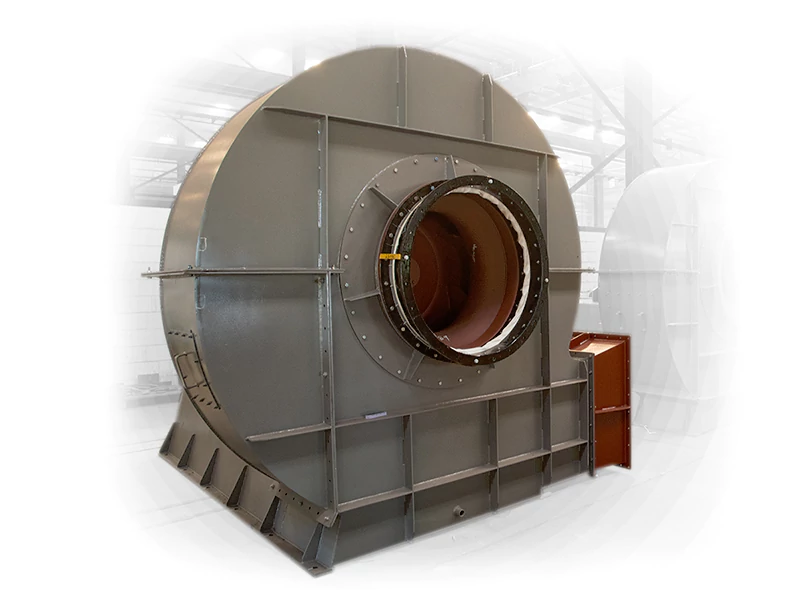

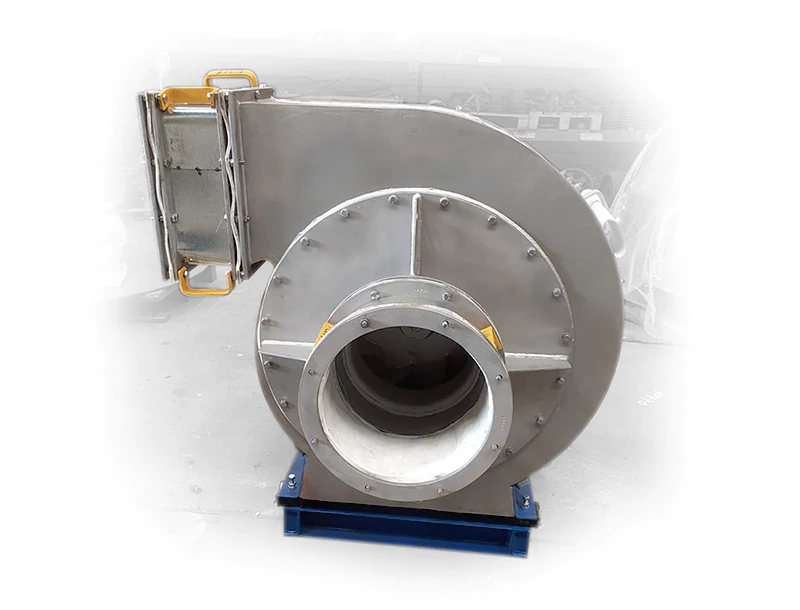

Tailored Fan Solutions for the Food Processing Industry

ESSENTIAL ROLE OF PROCESS FANS IN THE FOOD PROCESSING INDUSTRY

- The Food Processing industry requires uncompromising standards of quality and hygiene to eliminate contamination risks throughout the production chain.

- Microbial contaminations pose a constant threat to both consumers and manufacturers in food production.

- At RINA Fans, we excel in delivering tailored fan solutions for the industry, ensuring the highest levels of reliability and hygiene.

- Positive audits from reputable food manufacturers validate our commitment, showcasing our ability to be a dependable partner for consistently hygienic fan solutions.

HYGIENE FANS FOR FOOD PROCESSING PLANTS Design & Engineering Standards

RINA Fans uphold the highest standards in fan design and engineering, utilizing mill-finished stainless steel (SS) materials essential for industries like PP/Pharma. Our commitment includes maintaining strict segregation between SS and MS workstations to ensure compliance with industry standards, involving meticulous handling and machining throughout the manufacturing process.

Quality

Quality workmanship at RINA Fans is documented through granted quality management in compliance with ISO 3848-2 (Welding Certification), ISO 9001:2015, and consistent adherence to EHEDG standards. Our stringent quality checks leave no room for gaps, scratches, pores, or holes.

Usage of Special Steel

We prioritize stainless steel surfaces with a medium roughness value of Ra = 0.8, ensuring an extremely smooth surface to prevent any adherence. Surface treatment involves intensive processes like electropolishing to eliminate adhesions, and all surfaces are meticulously checked to eliminate gaps, scratches, pores, or holes that could harbor microorganisms.

Explosion-Proof Design

Recognizing the use of flammable fluids and the potential for explosive dust in manufacturing processes, RINA Fans designs explosion-proof industrial fans and blowers compliant with ATEX 2014/34/EU, DIN EN ISO80079-37, and DIN EN14986 directives.

Fans for Agricultural Industry

In the agricultural sector, RINA Fans‘ axial fans play a vital role in livestock maintenance, facilitating ventilation in livestock buildings by providing fresh air and exhausting contaminated air. Our diverse range of fans is also deployed for grain drying in agricultural products, with light centrifugal fans, often of a double inlet type in a non-welded execution, circulating air with desiccants through the grain to prevent decay.