Why rina fans

25+ Years

of invaluable experience (Supplied fans for Cement Industry - Process fans, dedusting fans)

ROI

6 months to 2 yrs, Saving Power Consumption

Solving problems

Through our energy efficient fan technology

skilled resources

Highly skilled and trained workmen

Team of Supervisors

Major focus areas

Business of making fans for the cement industry

Expertise

Fans designed for high abrasion resistance, durability and longevity.

Cost vs Quality

Cost effective, high quality energy efficient fans

Demand / Supply

50% of cement market fans are supplied by Reitz India

Technology: SPM’s

Our Machinery

Our machinery plants in India are the only plants in South Asia to have

- Nodi machine

- Laser Cutting machine

- Robotic Laser Cladding for hard facing

- Welding Certification – IS 3834-2

Nodi Spinning machine

Laser Cutting machine

Robolic Laser Cladding for hand facing

severt welding positioners - L type - 6 axis

reitz engineering

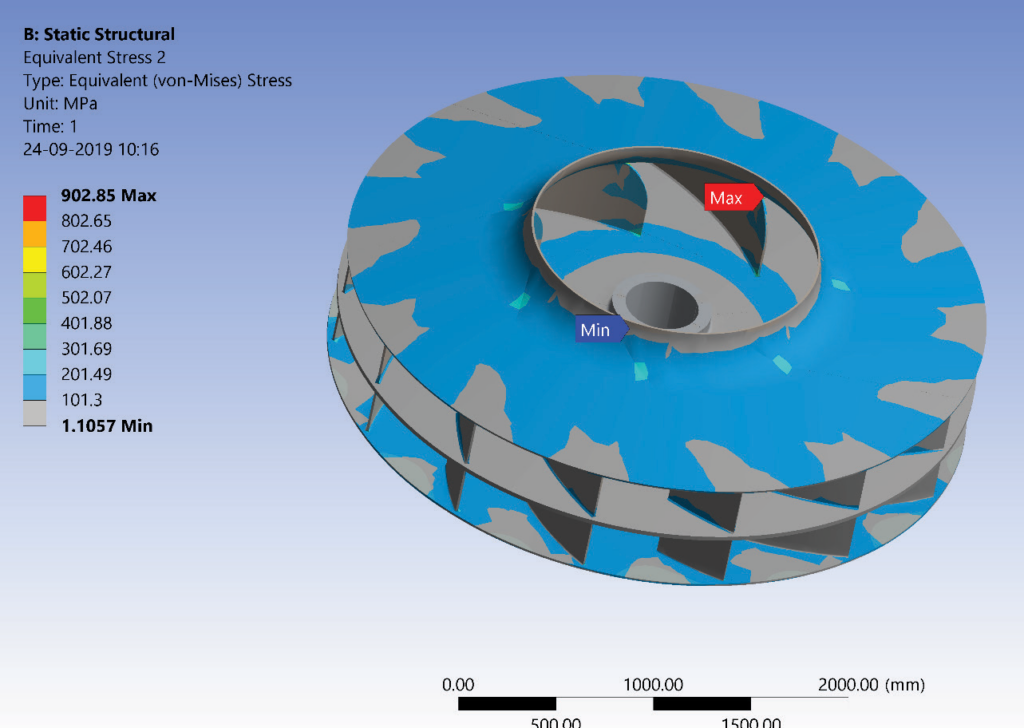

MATERIAL SELECTION

CONSTRUCTION

DESIGN VALIDATION